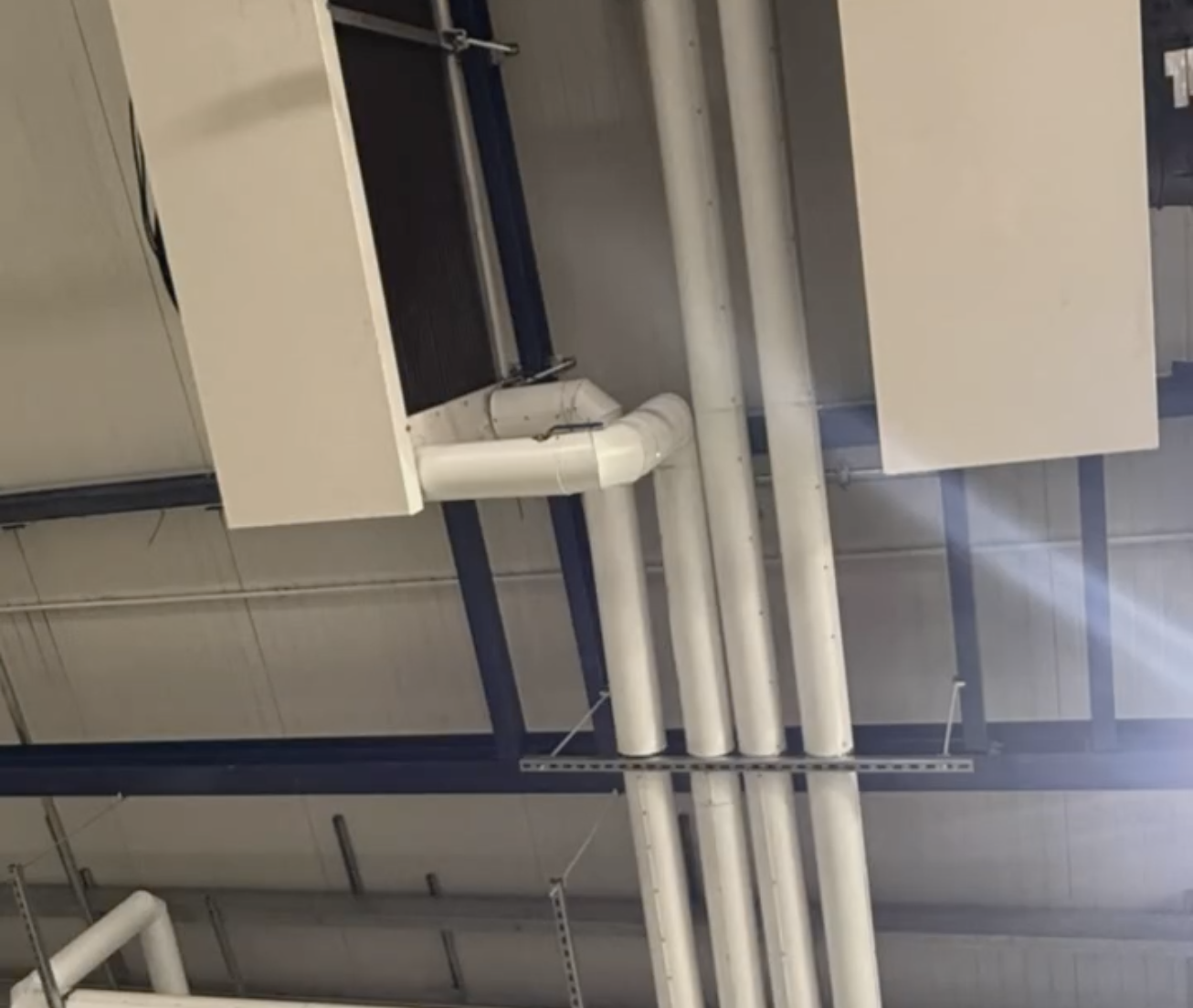

Acoustic Pipe Lagging Melbourne

Acoustic lagging is a specialised type of pipe insulation designed to reduce noise generated by fluid flow, plumbing operations, and mechanical systems. In large commercial buildings, apartment complexes, healthcare facilities, and mixed-use developments, managing sound transmission through pipework is essential for occupant comfort and building performance.

At Martis Laggers, we deliver expert acoustic pipe lagging services across Melbourne, helping builders, developers, and facility managers reduce unwanted noise from plumbing systems.

With over a decade of hands-on experience, we specialise in insulation that supports quiet, compliant, and comfortable spaces—particularly in multi-storey apartments, healthcare facilities, hotels, and commercial buildings.

Why Acoustic Pipe Lagging Matters

Noisy pipework can be a constant source of frustration in high-density environments. Wastewater movement, flushing, and pressure changes often create sound transfer through walls, ceilings, and floor slabs. Without proper acoustic insulation, these noises can travel between rooms and impact privacy, especially in residential and healthcare settings. Unmanaged plumbing noise can impact building performance and occupant satisfaction.

Noise reduction for residential and commercial environments

Whether it’s plumbing, HVAC, or drainage systems, uncontrolled noise can disrupt spaces. Acoustic lagging isolates the sound source and significantly dampens pipe-borne noise.

Enhanced living and working comfort

Provides a quieter connection—especially in apartments, aged care, or hotels, fosters better occupant satisfaction and improves the perception of quality.

Protect Your Building’s Value

Quiet, comfortable environments improve leasing appeal and long-term asset performance, particularly in residential towers, hotels, and healthcare facilities.

Is acoustic lagging worth it?

When budgets are tight, acoustic lagging can sometimes look like an easy line item to scale back. But in reality, cutting corners here often costs more in the long run.

For large-scale builds, the benefits far outweigh the upfront investment:

Avoid Costly Complaints & Retrofits

Poor soundproofing leads to tenant dissatisfaction, noise complaints, and in some cases—expensive remedial works.

Meet Acoustic Standards from Day One

With NCC and AS 2107 setting clear expectations for internal noise levels, acoustic lagging is often not optional—it’s compliance-critical.

Minimal Cost Compared to Fit-Out

In most projects, the cost of proper acoustic lagging is a fraction of the fit-out budget—but its impact on comfort and compliance is significant.

FAQs

What is the best material for acoustic lagging?

The most effective acoustic lagging materials depend on the type of system, the noise levels involved, and project requirements. Common solutions include:

Mineral Wool Pipe Insulation: Dense and fire-resistant, Mineral wool insulation is ideal for wrapping noisy waste and mechanical services. It provides both thermal and acoustic benefits.

Mass-Loaded Vinyl (MLV) Acoustic Insulation: MLV is primarily used for acoustic pipe lagging to reduce noise transmission through pipes. It is dense and flexible, making it effective in dampening sound.

Composite Systems: Often a combination of mineral wool and MLV, designed to meet NCC requirements for acoustic and fire performance in high-rise and commercial projects

Reflective Foil Insulation: Reflective foil insulation includes a layer of reflective material, such as aluminium, that helps to reflect radiant heat. It is often used in combination with other insulation materials for added thermal protection.

The “best” option depends on whether your priority is noise compliance, fire performance, or multi-service riser applications. Consulting with our acoustic lagging specialists ensures the right balance of performance and compliance for your project.

How thick should acoustic lagging be?

Thickness is critical when it comes to acoustic performance. Too thin, and noise transmission won’t be reduced effectively; too bulky, and it can create space or installation issues.

Mineral wool thickness typically ranges from 25mm to 50mm, depending on service type and noise level.

MLV sheets are usually 2–5mm thick but add significant acoustic mass when combined with mineral wool.

Large commercial projects often require thicker composite systems to meet NCC or AS 2107 standards for habitable spaces.

Ultimately, thickness should be determined by the pipe size, noise level, and compliance requirements of the project.

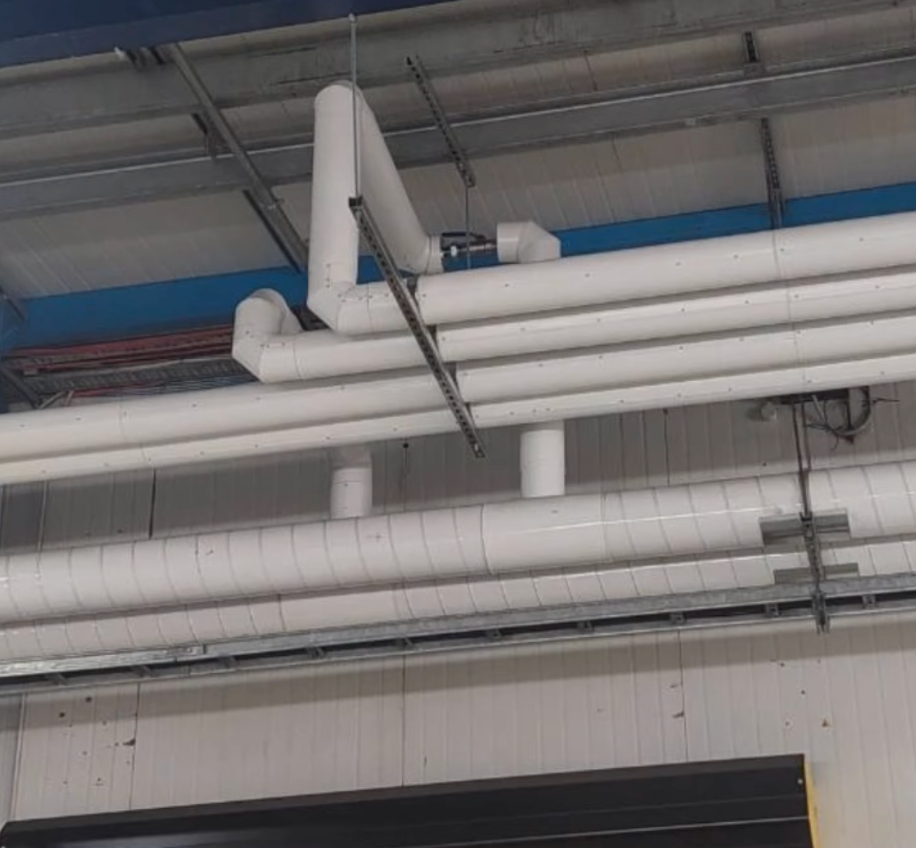

Do both PVC and copper pipes need acoustic lagging?

Yes — both PVC and copper pipes transmit noise.

PVC pipes often carry waste or stormwater and can cause disruptive flushing or gurgling sounds if not properly lagged.

Copper pipes, particularly in mechanical and HVAC systems, can transmit vibration and water hammer noise through walls and floors.

Acoustic lagging ensures both pipe types meet noise compliance standards, protect tenant comfort, and avoid costly retrofits after handover.

Does acoustic lagging save money?

By addressing noise issues effectively from the start, you avoid retrofitting and rework, resulting in better lifecycle performance and smoother handovers.