High Quality Lagging & Cladding: Chilled Water Pipes Done Right

In large cold storage facilities, data centres, and high-capacity commercial plants, chilled water systems are more than just a utility — they're critical to keeping operations running at peak efficiency. Without the right pipe insulation and cladding strategy, you can risk heat gain, condensation issues, or compliance issues slowing your project down.

In large cold storage facilities, data centres, and high-capacity commercial plants, chilled water systems are more than just a utility — they're critical to keeping operations running at peak efficiency. Without the right pipe insulation and cladding strategy, you can risk heat gain, condensation issues, or compliance issues slowing your project down.

At Martis Laggers, we work with Australia’s biggest builders, contractors, and facility managers to deliver chilled water pipe lagging and cladding solutions that perform from day one and stands the test of time.

Why Lagging Matters for Large Projects

Chilled water systems in big builds face challenges that smaller projects never see — longer pipe runs, higher load demands, and more complex compliance requirements. The right lagging solution delivers:

- Thermal Efficiency – Minimises energy loss across long pipe networks, keeping chillers working at peak performance.

- Condensation Control – Prevents moisture damage, corrosion, and mould growth — especially in humid or high-traffic zones.

- Asset Protection – Reduces wear and tear, extending the life of the chilled water system.

- Compliance Confidence – Meets Australian standards for thermal performance, fire safety, and mechanical insulation.

The Importance of Cladding

Proper cladding isn’t just about appearance, it plays a critical role in protecting your investment and ensuring system performance.

Protects Insulation

Cladding shields pipe lagging from physical damage, impact, and wear in busy plant rooms or high-traffic areas.

Enhances Durability

Materials like Colourbond, aluminium, and stainless steel resist corrosion, moisture, and long-term environmental effects.

Supports Compliance

Certain cladding systems help meet fire ratings and regulatory requirements for mechanical services.

Maintains Aesthetic Standards

Clean, professional finishes reinforce a facility’s operational quality and corporate image.

Simplifies Maintenance

Accessible, robust cladding makes inspections, repairs, and cleaning easier, reducing downtime and operational disruption.

Our Proven Chilled Water Lagging Method

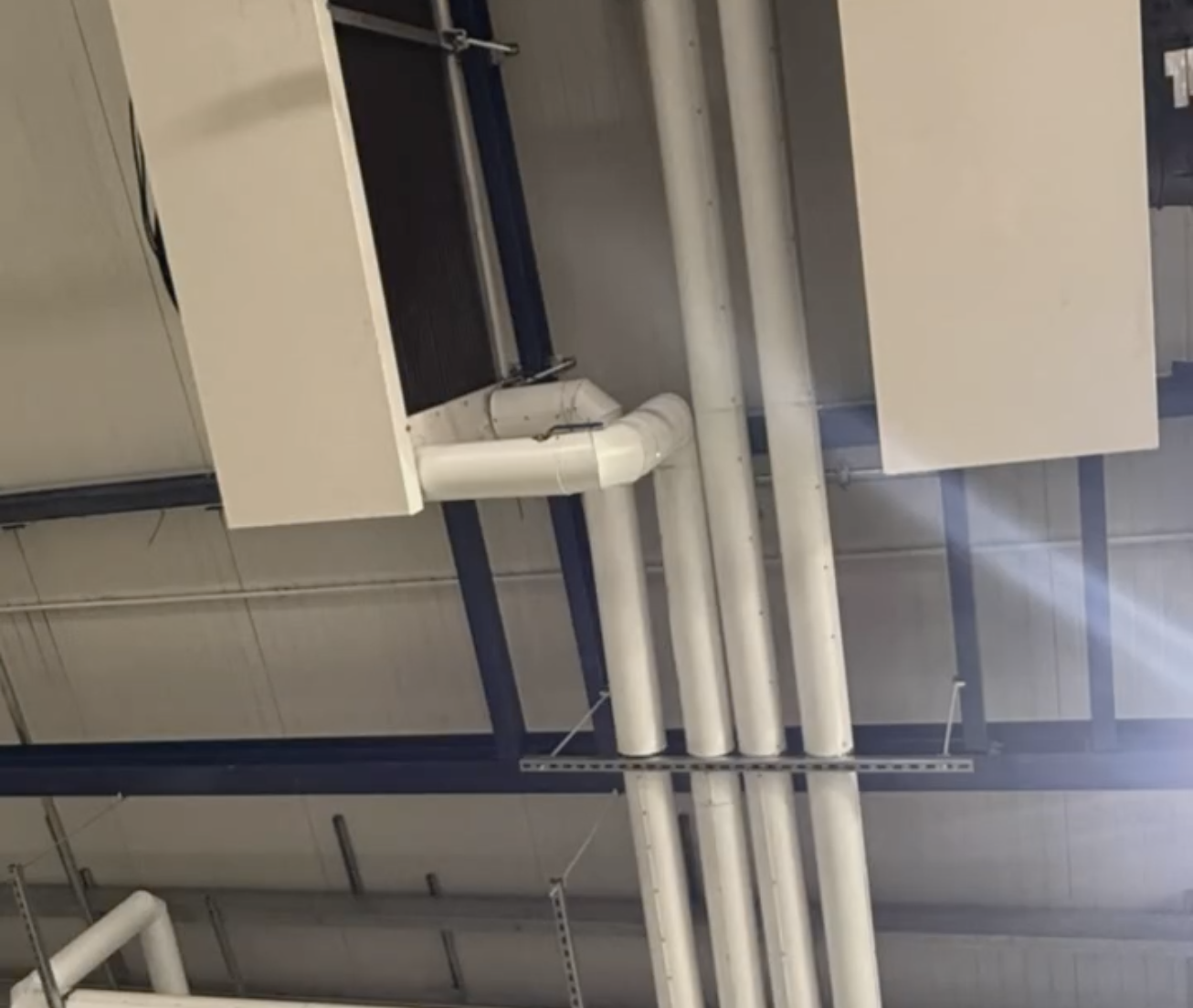

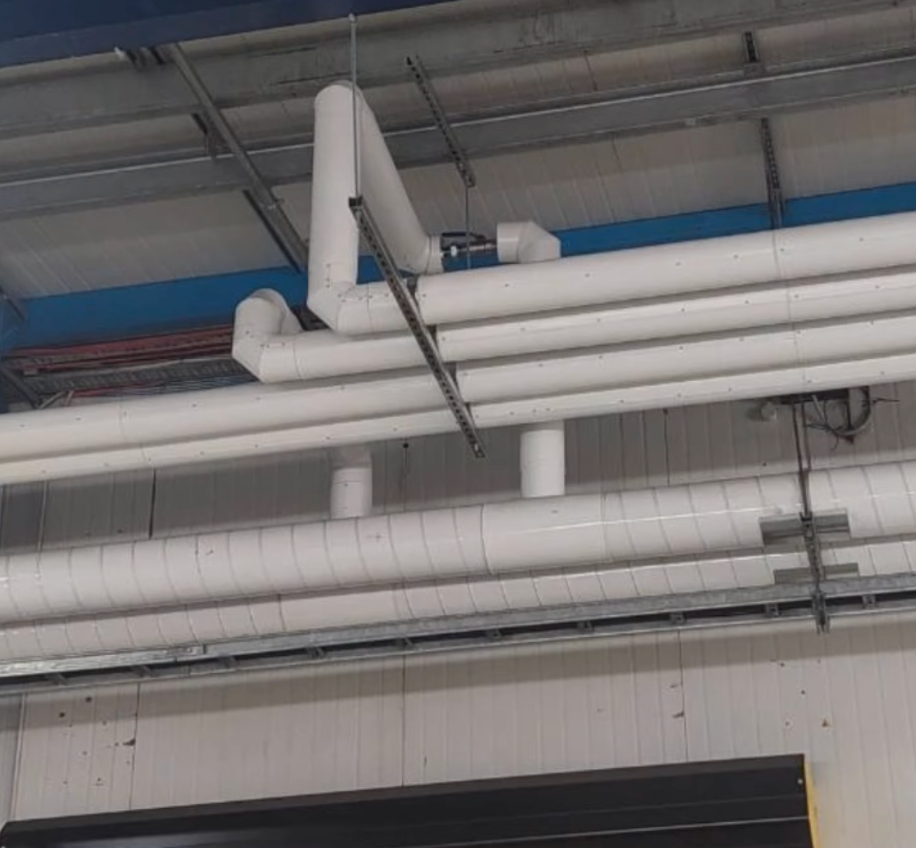

For a recent cold storage project, we used 50mm thick styrene insulation for maximum thermal retention and paired with Colourbond white gloss sheet metal cladding, delivering both performance and aesthetics.

This approach provided:

- Extra Protection – Durable cladding guards against physical damage in busy plant rooms.

- Clean, Professional Finish – A high-quality look that reflects the professionalism of the overall build.

- Long-Term Performance – Corrosion-resistant materials designed to perform for decades.

Cladding Solutions for Every Project Scenario

While styrene insulation plus sheet metal is ideal for many cold storage builds, other options include:

- Aluminium Cladding – Lightweight, corrosion-resistant and ideal for coastal projects.

- Stainless Steel – Durable and hygienic for food-grade or pharmaceutical facilities.

- PVC Cladding – Moisture-resistant and cost-effective for mechanical spaces.

- Custom Colourbond Finishes – Matches corporate branding or facility aesthetics.

Every project is different, that’s why we work with consultants and project managers to specify the right insulation and cladding combination for your environment, performance targets, and budget.

In Need of a Pipe Lagging & Cladding?

The right lagging and cladding ensures energy efficiency, compliance, durability, and a premium finish, without the costly risk of rework.

If your next project demands high-performance chilled water insulation and cladding, contact us and we’ll help you deliver it right the first time.