Pipe Cladding in Large-Scale Projects: Why It’s Non-Negotiable

When you’re managing a major commercial building such as a data centre, hospital, high-rise, or cold storage facility, every system is under scrutiny. Mechanical services, pipework, and insulation aren’t just background details; they’re integral to passing compliance, maintaining efficiency, and keeping stakeholders happy. One area often underestimated until it’s too late? Pipe cladding.

When you’re managing a major commercial building such as a data centre, hospital, high-rise, or cold storage facility, every system is under scrutiny. Mechanical services, pipework, and insulation aren’t just background details; they’re integral to passing compliance, maintaining efficiency, and keeping stakeholders happy. One area often underestimated until it’s too late? Pipe cladding.

Cutting corners on cladding can lead to costly rework, failed inspections, and long-term maintenance headaches. That’s why, for large-scale projects, pipe cladding isn’t just an aesthetic choice — it’s a compliance, performance, and longevity essential.

Why Pipe Cladding Matters in Commercial Builds

Cladding does far more than cover insulation. It’s the protective outer shell that ensures your lagging continues to perform under real-world conditions. In large builds, the risks of skipping or downgrading cladding are significant:

- Mechanical protection – Prevents damage to insulation from on-site traffic, equipment, and later maintenance access.

- Moisture resistance – Stops condensation and water ingress that compromise chilled water systems or refrigeration lines.

- Fire compliance – Certain cladding systems support passive fire performance across riser shafts and inter-tenancy walls.

- Durability – Withstands UV exposure, cleaning chemicals, or physical wear in plant rooms, rooftops, and external spaces.

- Aesthetic finish – For visible areas, like commercial kitchens or plant spaces, cladding provides a professional, compliant finish that’s easy to maintain.

In other words, cladding safeguards your investment, ensuring the insulation specified on paper actually delivers in practice.

Cladding Materials for Large Projects

Not all cladding materials are created equal, and the right choice depends on your project’s scale, service type, and environment. Here are some of the most effective cladding options used across Melbourne’s largest builds:

- Aluminium Cladding – Lightweight, corrosion-resistant, and ideal for external plant rooms or rooftops.

- Stainless Steel Cladding – Robust, hygienic, and perfect for hospitals, food production facilities, and high-clean environments.

- Colourbond Cladding – A durable, weather-resistant option that also allows for aesthetic finishes in exposed plant areas.

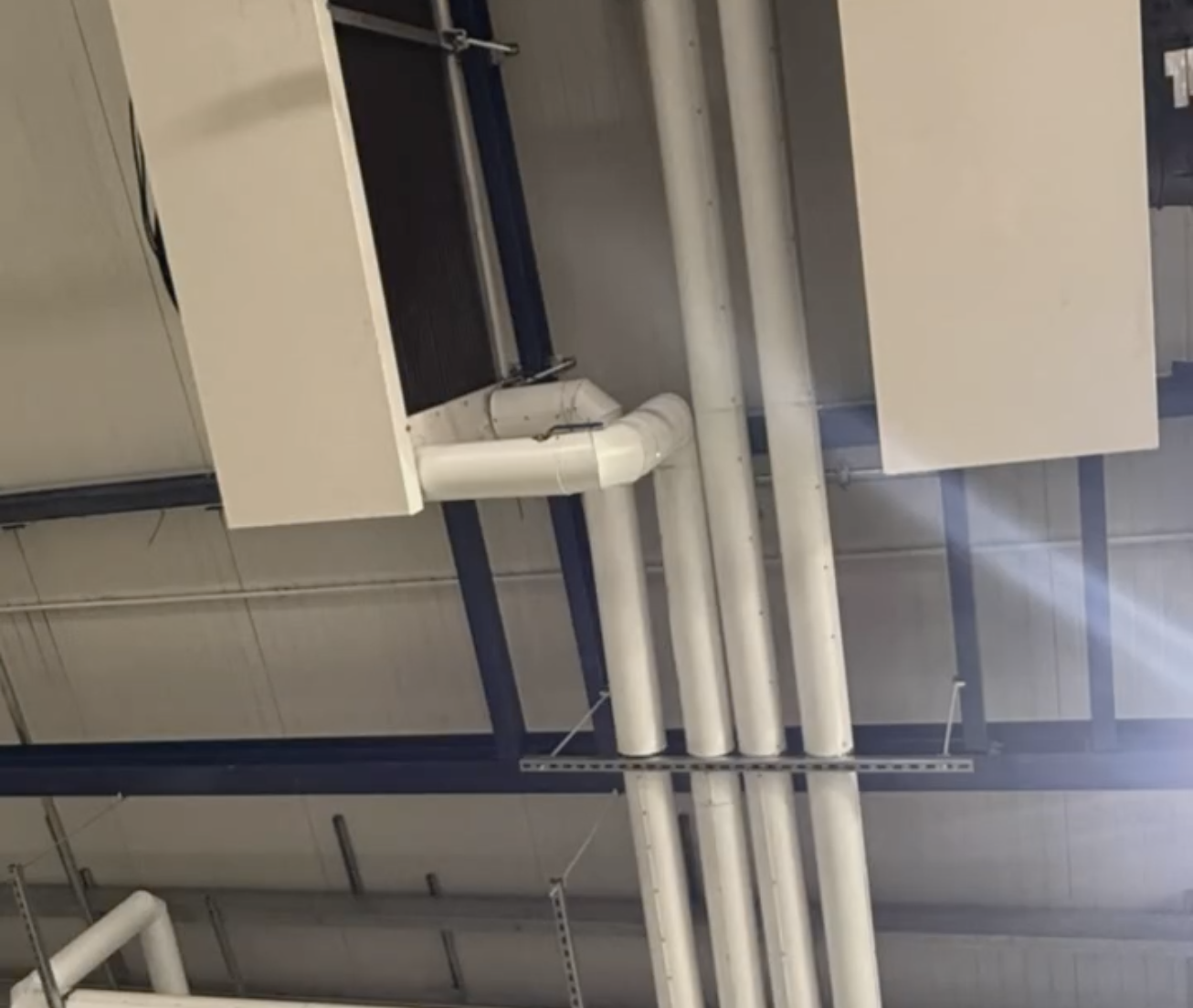

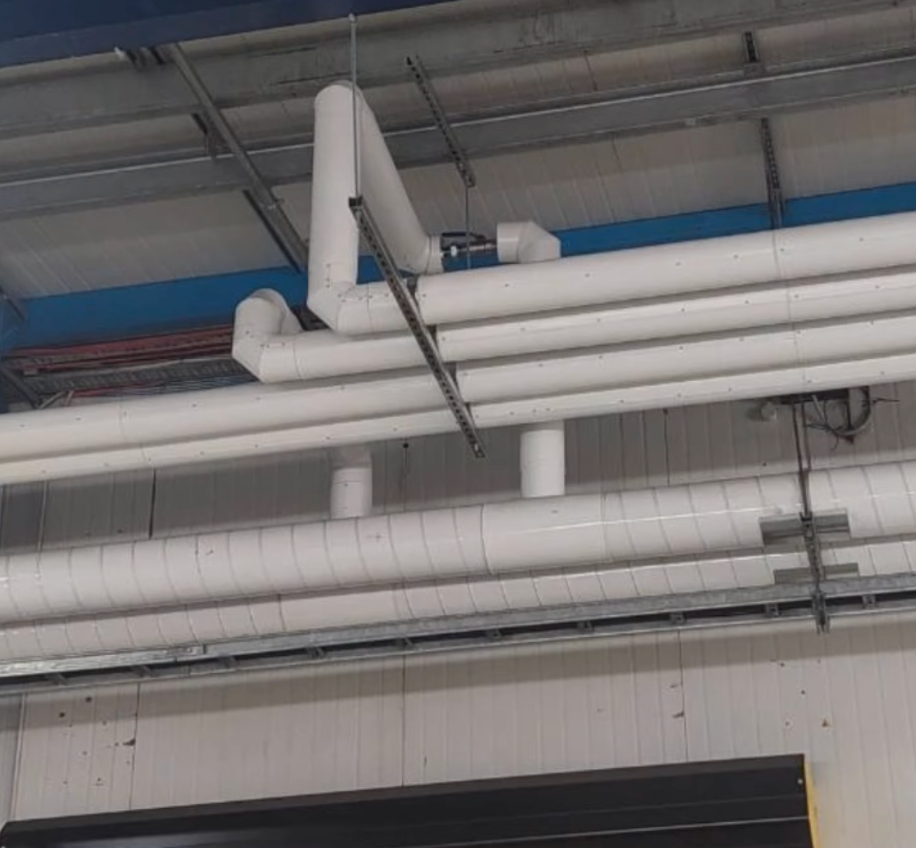

- PVC Cladding – Cost-effective and easy to install, suitable for internal mechanical systems and chilled water lines.

Each option offers distinct advantages. For instance, a cold storage warehouse may lean on PVC or aluminium for condensation control, while a hospital project will prioritise stainless steel for hygiene and compliance.

Pipe Lagging and Cladding: Why They Go Hand in Hand

Lagging and cladding aren’t two separate decisions — they’re a combined system. Lagging delivers the thermal, acoustic, and fire performance, while cladding protects that performance for the long term. Without proper cladding, even the best lagging materials can be damaged, compromised by moisture, or fail to meet compliance.

In large commercial projects, it’s this combination that ensures your systems not only meet NCC and AS standards but also continue to perform years after handover. Think of lagging as the engine, and cladding as the protective shell that keeps it running at its best.

Pipe Cladding and Compliance

Australia’s National Construction Code (NCC) and related standards don’t just require insulation to perform; they also mandate protection and verification of those systems. Failing to specify or install appropriate cladding can result in:

- Non-compliance with thermal performance requirements

- Increased risk of condensation-related defects

- Failed inspections or certification delays

- Rework costs that push projects over budget

For builders, project managers, and consultants, cladding needs to be locked into the specification stage — not treated as an afterthought. It’s the difference between a system that simply looks finished and one that’s built to last.

Don’t Leave Cladding to Chance

For over a decade, Martis Laggers has supported Melbourne’s largest builders and contractors with pipe insulation and cladding solutions. We work across commercial and industrial builds to ensure:

- The right cladding materials are matched to your system requirements

- Installations meet NCC, AS/NZS, and project-specific compliance standards

- Work is carried out cleanly and efficiently, even in tight or high-access areas

- All documentation is provided for certification and handover

If you’re overseeing a major project and need insulation and cladding done right the first time, Martis Laggers is here to help. Let’s make sure your systems perform on paper, in inspections, and in operation for years to come.

Disclaimer

This article is provided free of charge for public information. We do not guarantee, and accept no legal liability for, the accuracy, reliability, currency, or completeness of the content or any linked material. Users should apply their own judgment and verify the material’s relevance to their needs. This article is a general summary and not a substitute for legal or professional advice. Users should seek appropriate advice for their circumstances. Any third-party views expressed do not necessarily reflect ours or imply endorsement.