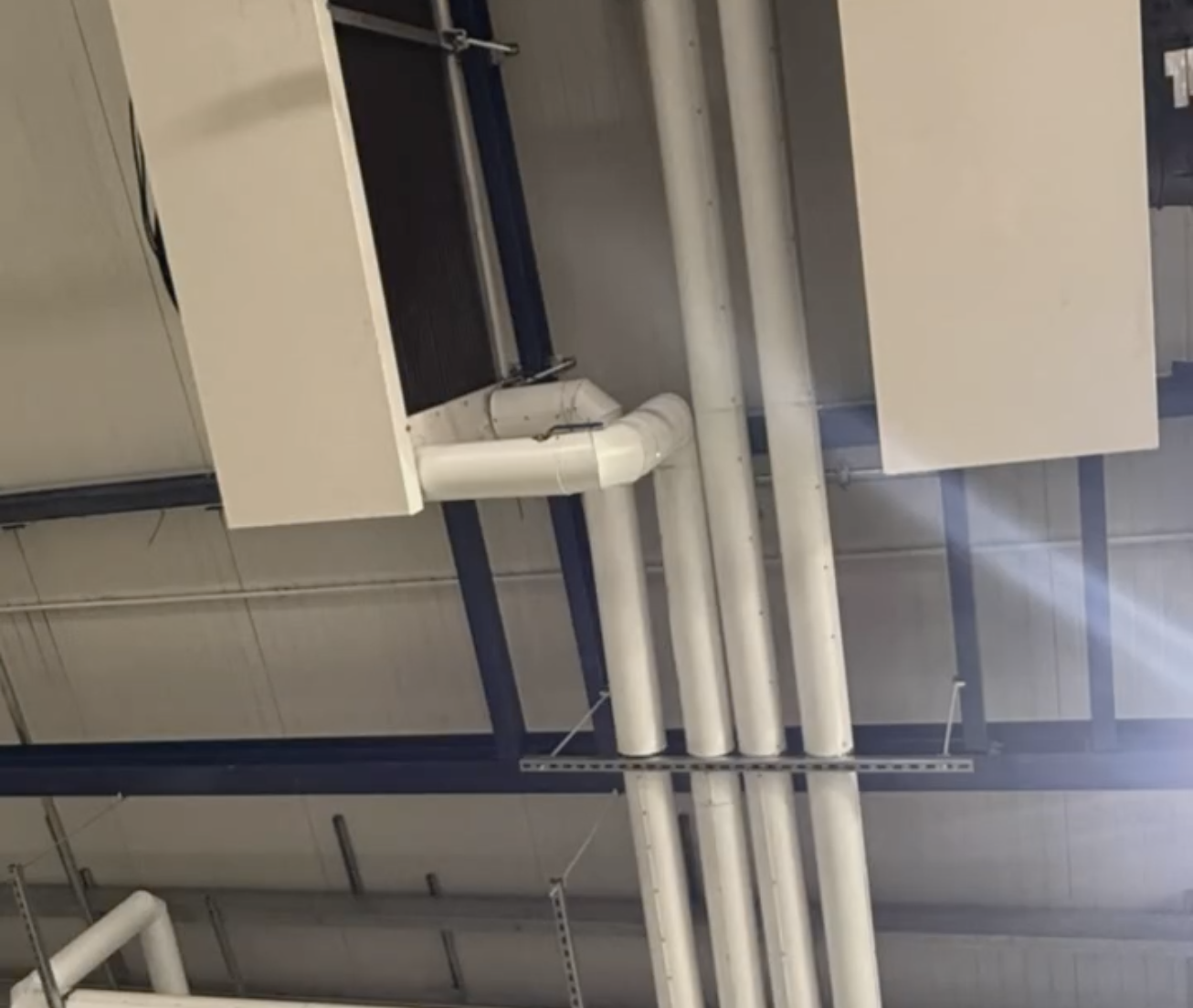

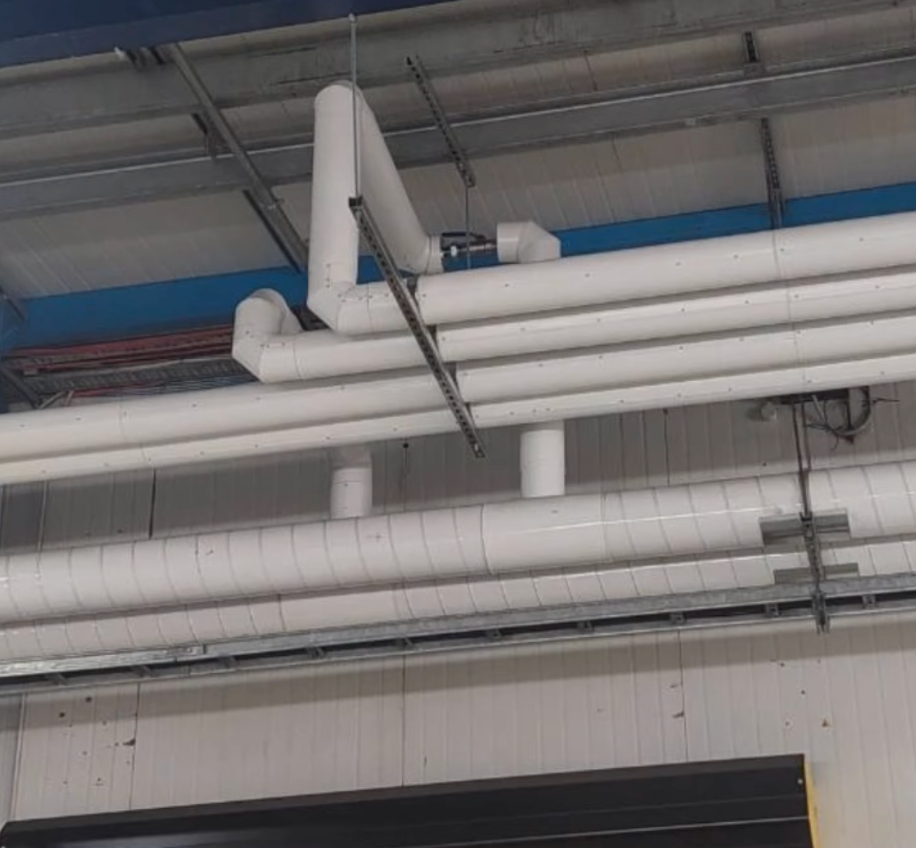

Thermal Lagging Melbourne

At Martis Laggers, we specialise in thermal pipe lagging, providing vital solutions to address energy efficiency concerns.

Thermal pipe lagging plays a key role in maintaining temperature control within pipelines. This not only minimises heat loss but also optimises energy consumption, making it a crucial factor in reducing operational costs and environmental impact.

Our dedicated team of experts collaborates closely with clients to identify the root causes of energy waste within their infrastructure. By conducting thorough assessments, we tailor solutions that best suit each client's specific needs.

Our expertise extends to various industries, catering to the diverse needs of commercial, industrial, and residential clients. Our services encompass the installation of high-quality thermal insulation materials, ensuring that each project adheres to the highest industry standards. By investing in the services provided by Martis Laggers, clients can expect a considerable reduction in energy consumption, lower utility bills, and a reduced carbon footprint.

Reduction of Heat Transfer

Pipe lagging minimises the transfer of thermal energy (heat) between the fluid within the pipe and the external surroundings. For hot water or steam pipes, it keeps the heat from escaping into the ambient air. In cooling systems, it prevents heat from entering the chilled water.

Condensation Control

In addition to heat conservation, thermal pipe lagging can also prevent condensation on cold pipes. When cold pipes come into contact with warm, humid air, condensation can form on the pipe's surface. Insulation helps to keep the pipe temperature above the dew point, preventing condensation and potential issues like corrosion and mould growth.

Energy Efficiency

The reduced heat loss or gain achieved through thermal pipe lagging translates into energy savings. As less energy is required to maintain the desired temperature of the fluid, it leads to lower utility bills and a reduced environmental impact.

How does thermal pipe lagging work?

Thermal pipe lagging, is a protective covering applied to pipes and ducts to prevent heat loss or gain, depending on the specific application. This insulation material acts as a barrier, reducing the transfer of heat between the pipe and its surroundings.

The primary purpose of thermal pipe lagging is to minimise heat loss in hot water or heating systems and prevent heat gain in cooling systems. This insulation can be made from various materials, including fibreglass, foam, or mineral wool, depending on the specific requirements of the application.

When installed, the insulating material creates a barrier around the pipe, which significantly reduces the exchange of heat between the contents of the pipe and the surrounding environment.

FAQs

Is it worth lagging central heating pipes?

Indeed, by insulating your household pipes you can keep the heat in your hot water from escaping before it reaches the places where it's needed in your home. This can lead to long-term savings.

How much of a difference does insulating pipes make?

When you insulate your hot water pipes, they lose less heat, and you can have water that's 2°F–4°F hotter than with uninsulated pipes. This means you won't need to wait as long for hot water when you turn on the tap or shower, which saves water. Plus, you can lower your water heater's temperature setting.

Do you lag hot or cold pipes?

It is essential to lag both hot and cold water pipes. Insulating hot water pipes helps to retain heat, reducing energy consumption and ensuring that hot water reaches its destination without significant heat loss. Similarly, insulating cold water pipes prevents condensation and maintains the water's temperature, which can be particularly important in hot or humid climates. Proper insulation of both hot and cold pipes is a practical step in improving the efficiency and effectiveness of your plumbing system.

Does lagging pipes stop condensation?

Indeed, lagging pipes is crucial for preventing condensation. When pipes carry cold water, they tend to be cooler than the surrounding air. This temperature differential can cause moisture in the air to condense on the exterior of the pipes. By insulating or lagging the pipes, you create a barrier that limits the transfer of temperature between the pipe's surface and the surrounding air. As a result, condensation is significantly reduced, if not entirely prevented. Proper insulation is essential, especially in areas with high humidity, as it can help prevent issues such as water damage, mould growth, and corrosion caused by condensation.