Hot & Cold Pipe Lagging: Key to Big Project Efficiency

In medium-to-large commercial and multi-residential projects, hot and cold-water services aren’t just utilities — they’re essential systems that must perform under pressure. From high-rise towers and hospitals to education facilities and data centres, poorly insulated pipework can mean wasted energy, noise complaints, compliance failures, and ultimately costly reworks.

In medium-to-large commercial and multi-residential projects, hot and cold-water services aren’t just utilities — they’re essential systems that must perform under pressure. From high-rise towers and hospitals to education facilities and data centres, poorly insulated pipework can mean wasted energy, noise complaints, compliance failures, and ultimately costly reworks.

That’s where hot and cold water pipe lagging plays a critical role. When specified and installed correctly, it protects your build from unnecessary risks while improving performance from day one.

Why Hot Water Pipe Lagging Matters

For large projects, thermal efficiency is non-negotiable. Hot water systems consume significant energy, and without proper lagging, that energy is lost before it even reaches the tap.

The risks of overlooking thermal lagging include:

- Heat loss across long pipe runs, driving up operating costs

- Overworked boilers and heaters, shortening system lifespan

- Compliance issues with Section J of the NCC, where minimum R-values must be met

- Discomfort for occupants, with inconsistent hot water delivery

By insulating with high-performance materials like fibreglass or mineral wool (often foil-faced for extra protection), hot water systems retain energy, reduce running costs, and pass compliance on the first inspection.

Why Cold Water Pipe Lagging Is Just as Important

Cold and chilled water lines face a different challenge: condensation control.

Without the right insulation and vapour barriers, condensation can form on pipe surfaces, leading to:

- Water damage to ceilings, walls, or nearby services

- Mould growth in risers and plant rooms

- Corrosion of pipework and fixings

- Failed inspections due to moisture-related defects

Closed-cell foam with integrated vapour barriers is the go-to solution for cold and chilled water systems in large-scale projects. It keeps pipe surfaces dry, protects building finishes, and ensures long-term durability.

Beyond Thermal: Acoustic and Fire Considerations

In multi-residential and commercial builds, water pipes don’t just carry water — they carry noise. Plumbing thuds, water hammer, and waste pipe noise can all travel through walls and into occupied spaces.

By integrating acoustic lagging (such as mineral wool combined with mass-loaded vinyl), consultants and builders can minimise disruption and deliver quieter, more liveable environments.

And for pipes running through fire-rated zones, lagging materials like mineral wool contribute to passive fire protection — ensuring services meet both AS/NZS 1530.3 fire test standards and NCC requirements.

The Right Materials for the Right System

Different systems require different lagging solutions. For water pipes in large projects, materials need to be selected not just for insulation, but also for long-term durability.

Some of the most effective options include:

- Closed-cell foam with vapour barrier – ideal for chilled water pipes to prevent condensation

- Fibreglass or mineral wool with foil facing – suitable for hot water and HVAC systems

- Composite lagging with acoustic wraps (MLV) – for waste or water systems where noise transfer is a concern

At Martis Laggers, we don’t take a one-size-fits-all approach. We review your mechanical specs and provide tailored recommendations to suit your build.

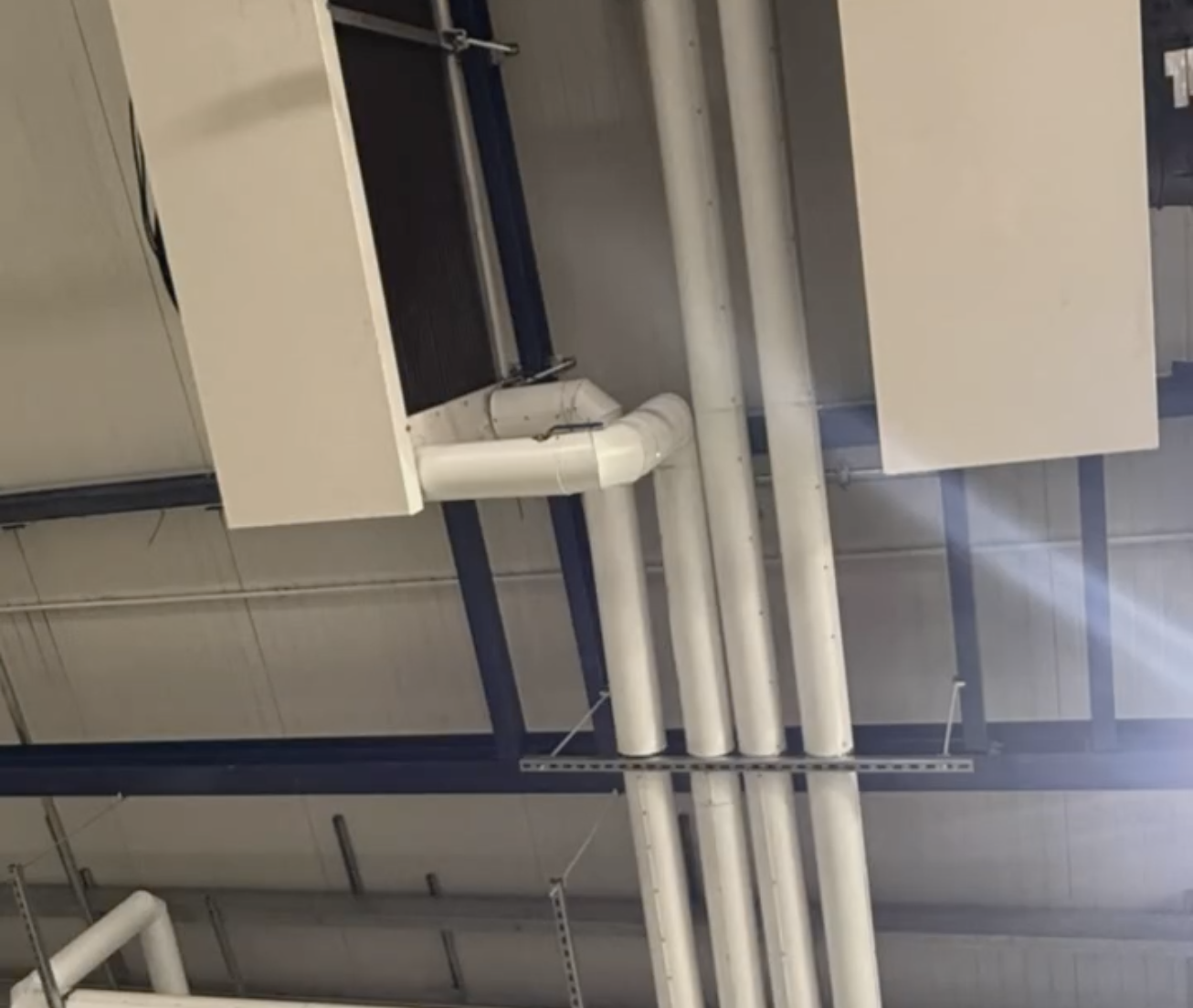

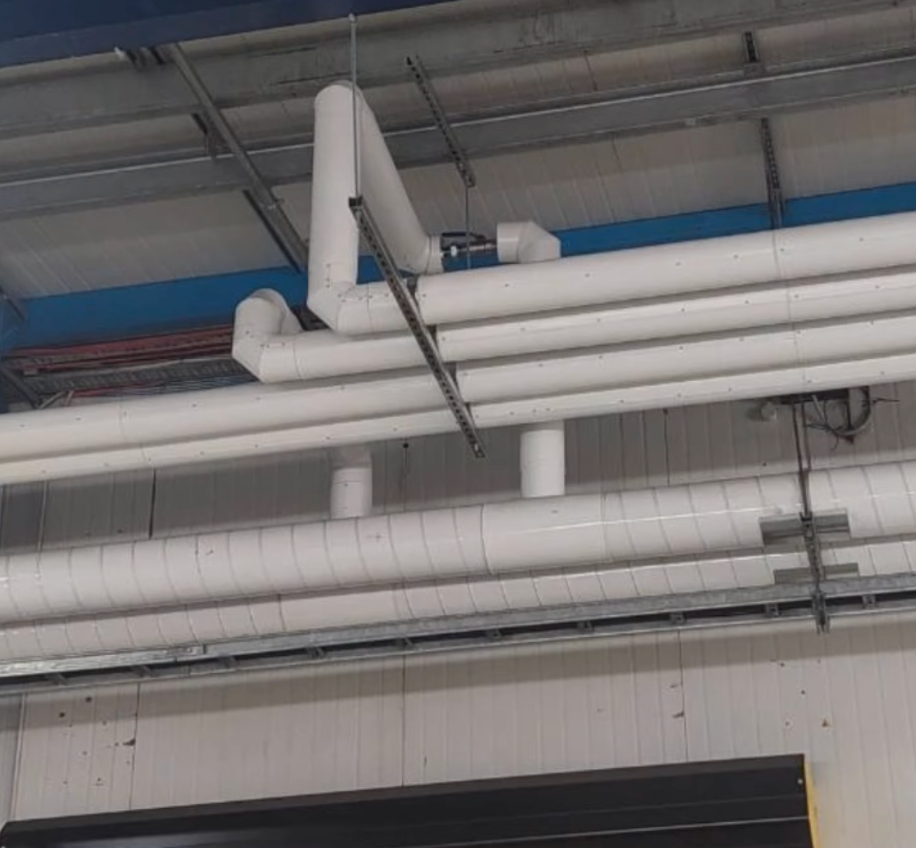

Lagging and Cladding: A Complete System

Lagging alone won’t guarantee performance in large-scale builds. Without protective cladding, insulation is exposed to moisture, UV, or mechanical damage during and after construction.

That’s why hot and cold-water lagging systems are often finished with aluminium, stainless steel, PVC, or Colourbond cladding — ensuring the insulation continues to perform while meeting hygiene, durability, and aesthetic needs.

Don’t Let Lagging Hold Up Your Next Build

Condensation, compliance issues, and reworks are the last things any project manager, consultant, or builder needs at final inspection. Getting it right from the start saves rework, avoids disputes, and ensures your build performs exactly as intended. Get in touch with our team today and we’ll make sure your pipe lagging is done right from the start.

Disclaimer

This article is provided free of charge for public information. We do not guarantee, and accept no legal liability for, the accuracy, reliability, currency, or completeness of the content or any linked material. Users should apply their own judgment and verify the material’s relevance to their needs. This article is a general summary and not a substitute for legal or professional advice. Users should seek appropriate advice for their circumstances. Any third-party views expressed do not necessarily reflect ours or imply endorsement.