Expert Guide: The Process of Pipe Insulation by Martis Laggers

In the realm of efficient energy management and infrastructure maintenance, pipe insulation stands out as a crucial aspect. Whether in residential, commercial, or industrial settings, properly insulated pipes play a vital role in conserving energy, preventing heat loss, and ensuring system integrity. Martis Laggers, a renowned pipe insulation specialist, follows a meticulous process to deliver top-notch insulation solutions tailored to the unique needs of each client. Let's delve into the comprehensive process undertaken by Martis Laggers in executing pipe insulation projects.

1. Initial Assessment:

Every successful pipe insulation project begins with a thorough assessment of the existing infrastructure and the specific requirements of the client. Martis Laggers' team conducts a comprehensive evaluation, taking into account factors such as pipe material, diameter, location, surrounding environment, and intended purpose of insulation.

2. Material Selection:

Based on the assessment findings and client preferences, Martis Laggers selects the most suitable insulation materials for the project. These may include foam insulation, fiberglass, mineral wool, or other specialised materials known for their thermal efficiency, durability, and compliance with industry standards.

3. Preparation and Safety Measures:

Before commencing insulation work, Martis Laggers ensures proper preparation of the work area and implements stringent safety measures. This includes securing necessary permits, preparing the pipes for insulation application, and adhering to safety protocols to protect both workers and occupants of the premises.

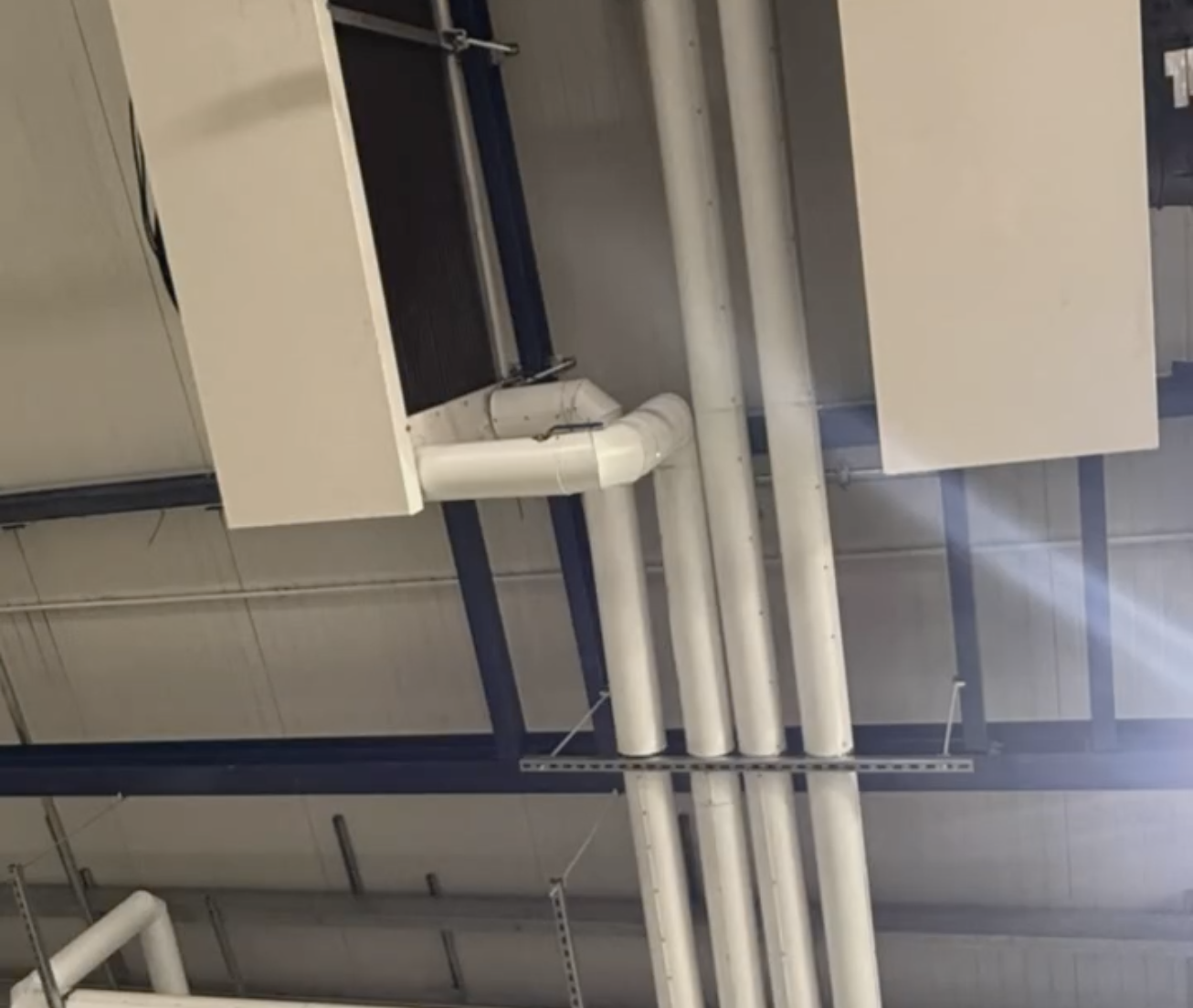

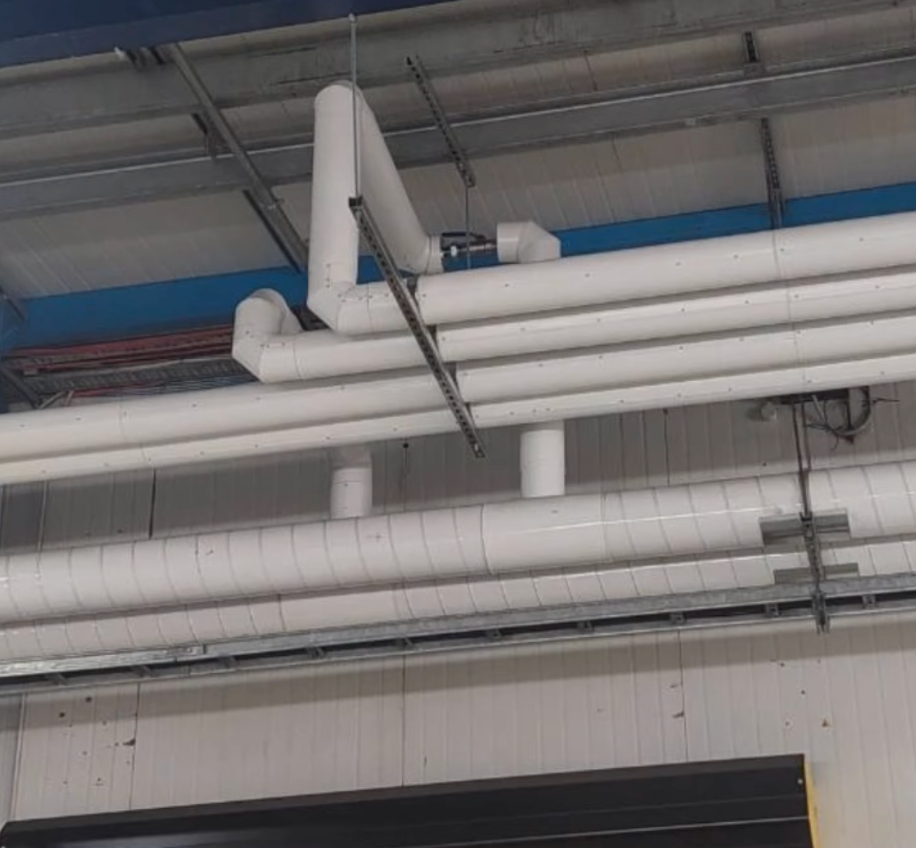

4. Application of Insulation:

With meticulous attention to detail, Martis Laggers' expert technicians proceed with the application of insulation material to the pipes. Whether wrapping, spraying, or applying rigid insulation, they ensure precise coverage and proper sealing to minimise heat transfer and maximise energy efficiency.

5. Customisation and Optimisation:

Martis Laggers understands that each pipe insulation project is unique, requiring customized solutions to address specific challenges effectively. Their team employs advanced techniques and innovative approaches to optimise insulation performance, taking into account factors such as temperature fluctuations, moisture resistance, and long-term durability.

6. Quality Assurance and Testing:

Upon completion of insulation installation, Martis Laggers conducts rigorous quality assurance checks and testing to ensure the integrity and effectiveness of the insulation system. This may involve thermal imaging, pressure testing, or other diagnostic methods to identify any potential issues and ensure compliance with industry standards.

7. Documentation and Client Handover:

Martis Laggers believes in transparency and accountability throughout the project lifecycle. Upon successful completion of the pipe insulation work, they provide comprehensive documentation detailing the materials used, installation procedures, test results, and maintenance recommendations. This ensures that clients have all the necessary information to maintain and monitor the performance of their insulated pipes.

8. Ongoing Support and Maintenance:

Beyond the completion of the project, Martis Laggers remains committed to providing ongoing support and maintenance services to their clients. Whether it's routine inspections, repairs, or upgrades, their team is readily available to address any concerns and ensure the continued efficiency and longevity of the pipe insulation system.

Martis Laggers sets the benchmark for excellence in pipe insulation services through their meticulous approach, commitment to quality, and dedication to customer satisfaction. By following a systematic process that encompasses assessment, material selection, application, testing, and ongoing support, they deliver superior insulation solutions tailored to the unique needs of each client. With Martis Laggers, you can trust that your pipes are in capable hands, ensuring optimal performance, energy efficiency, and peace of mind for years to come.

Disclaimer

This website is aimed at disseminating information free of charge for the benefit of the public. We do not guarantee, and accept no legal liability whatsoever arising from or connected to, the accuracy, reliability, currency or completeness of any material contained on this website or on any linked site. We recommend that users exercise their own skill and care with respect to their use of this website and that users carefully evaluate the accuracy, completeness and relevance of the material on the website for their purposes. The material on this website is a summary only of the subject matter covered and is not intended to be nor should it be relied on as a substitute for legal or other professional advice. Users should obtain any appropriate professional advice relevant to their particular circumstances. The material on this website may include the views or recommendations of third parties, which do not necessarily reflect the views of ours, or indicate its commitment to a particular course of action.