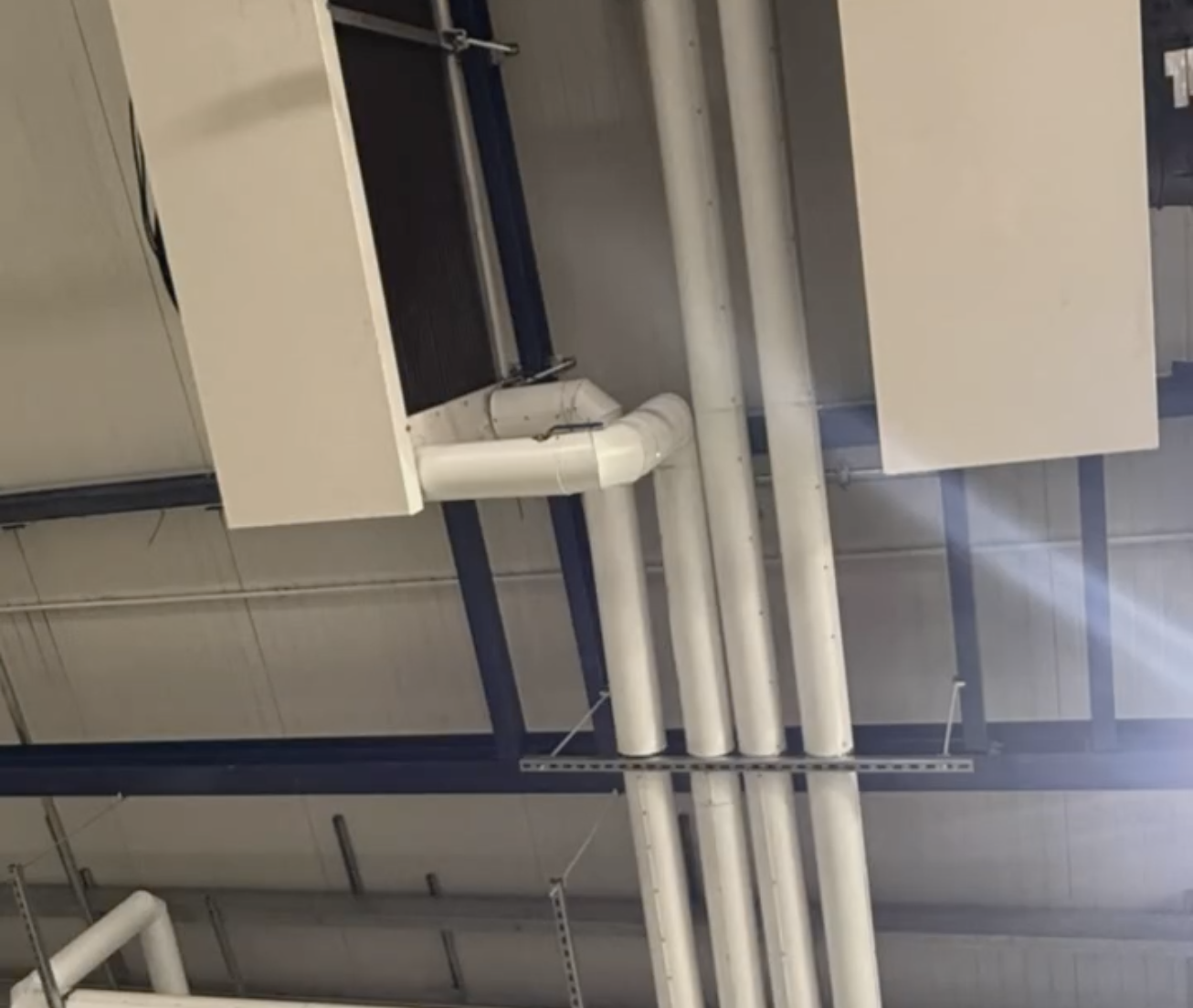

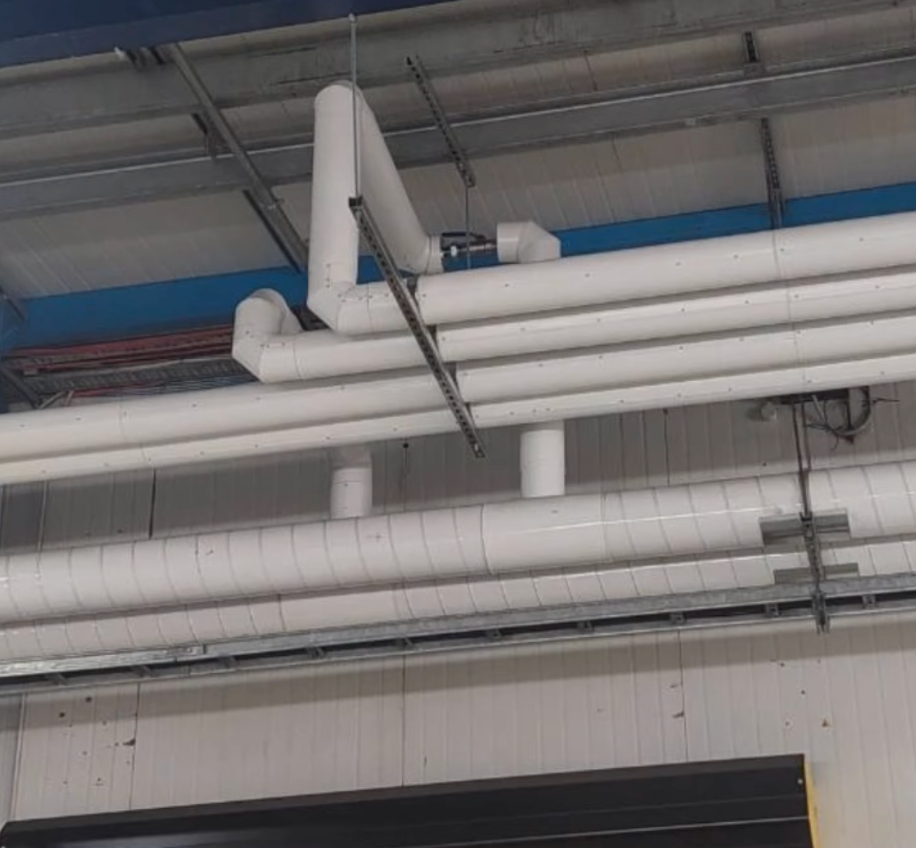

Frequently Asked Questions about Pipe Lagging and Insulation

What is pipe lagging?

Pipe lagging entails insulating pipes to prevent heat loss, sustain temperature levels, and diminish energy consumption. It encompasses enclosing pipes with insulating material to establish a barrier between the pipe and its surroundings.

Why is pipe lagging essential?

Pipe lagging holds significance for several reasons:

Energy efficiency: It averts heat loss, reducing energy usage and associated expenses.

Freeze prevention: Insulating pipes guards against freezing in cold conditions, minimizing the risk of pipe bursts and water damage.

Condensation management: Lagging inhibits condensation buildup on pipes, averting corrosion and mold growth.

Safety: Insulated pipes are safer to handle, lowering the likelihood of burns or accidents.

What are the advantages of pipe insulation?

Key benefits of pipe insulation include:

Energy conservation: Insulated pipes necessitate less energy to retain desired temperatures, resulting in reduced utility costs.

Temperature regulation: Insulation maintains consistent temperatures in pipes, ensuring optimal performance of systems like HVAC and hot water.

Pipe longevity: Insulation extends the lifespan of pipes by shielding them from corrosion, freezing, and environmental elements.

Environmental impact: Decreased energy consumption leads to reduced greenhouse gas emissions, making pipe insulation environmentally friendly.

What insulation materials are available for pipe lagging?

Various insulation materials suitable for pipe lagging include:

Foam insulation: Such as polyethylene or rubber foam, lightweight and easy to install.

Fiberglass insulation: Made from spun glass fibers, offering excellent thermal resistance.

Mineral wool insulation: Comprising rock or slag fibers, providing high-temperature resistance and fire protection.

Reflective foil insulation: Featuring a reflective surface to minimize radiant heat transfer.

How can I determine if my pipes require lagging or insulation?

Indications that your pipes may need lagging or insulation include:

Increased energy bills due to inefficient heating or cooling.

Cold or condensation-covered pipes.

Pipes in unheated or exposed areas vulnerable to freezing.

Systems experiencing temperature fluctuations or inconsistent performance.

Is DIY installation of pipe lagging feasible, or should I seek professional assistance?

While some individuals may be capable of installing pipe lagging independently, it's generally advisable to enlist professional services for optimal results. Professionals can assess your specific requirements, recommend suitable materials, and ensure correct installation for maximum effectiveness and durability.

What is the typical lifespan of pipe lagging?

The longevity of pipe lagging can vary depending on factors like insulation material, environmental conditions, and maintenance practices. Nonetheless, properly installed and maintained pipe lagging can endure for many years, delivering prolonged energy savings and pipe protection.

Is pipe lagging compatible with all pipe types?

Pipe lagging can be applied to various pipe materials, including metal, plastic, and composite types. However, it's essential to select appropriate insulation materials and installation methods based on the specific characteristics and needs of your pipes and systems.

Can pipe lagging assist with noise reduction?

Yes, pipe lagging can help minimize noise transmission through pipes, particularly in plumbing and HVAC systems. Insulating materials absorb sound vibrations, resulting in quieter operation and enhanced comfort in residential, commercial, and industrial settings.

Are there any maintenance requirements for pipe lagging?

While pipe lagging itself requires minimal maintenance, it's crucial to periodically inspect it for signs of damage, wear, or deterioration. Promptly addressing any tears, gaps, or loose fittings is essential to preserve insulation effectiveness and ensure ongoing energy efficiency and pipe protection.

Disclaimer

This website is aimed at disseminating information free of charge for the benefit of the public. We do not guarantee, and accept no legal liability whatsoever arising from or connected to, the accuracy, reliability, currency or completeness of any material contained on this website or on any linked site. We recommend that users exercise their own skill and care with respect to their use of this website and that users carefully evaluate the accuracy, completeness and relevance of the material on the website for their purposes. The material on this website is a summary only of the subject matter covered and is not intended to be nor should it be relied on as a substitute for legal or other professional advice. Users should obtain any appropriate professional advice relevant to their particular circumstances. The material on this website may include the views or recommendations of third parties, which do not necessarily reflect the views of ours, or indicate its commitment to a particular course of action.