What to Include in Your Pipe Lagging Specification: A Guide for Corporate Consultants

When it comes to large-scale commercial or multi-residential projects, one of the most overlooked but critical elements of your mechanical specification is pipe lagging. Pipe lagging is often a small line item on the spec sheet, but its role in thermal efficiency, acoustic performance, and compliance is anything but minor. Your insulation spec plays a major role in ensuring energy efficiency, acoustic comfort, fire safety, and full regulatory compliance.

When it comes to large-scale commercial or multi-residential projects, one of the most overlooked but critical elements of your mechanical specification is pipe lagging. Pipe lagging is often a small line item on the spec sheet, but its role in thermal efficiency, acoustic performance, and compliance is anything but minor. Your insulation spec plays a major role in ensuring energy efficiency, acoustic comfort, fire safety, and full regulatory compliance.

Getting it right early avoids rework, failed inspections, and post-installation disputes between builders, mechanical contractors, and certifiers. Here’s what consultants should consider including in their pipe lagging specifications.

Specify the Performance Requirements Upfront

A clear specification starts by outlining what the lagging needs to achieve in different parts of the project. For large builds, this typically includes: These typically include:

- Thermal insulation (e.g. for hot/chilled water, HVAC services)

- Acoustic insulation (e.g. to minimise noise through waste, water, and mechanical systems)

- Condensation control (especially in risers, plant rooms or chilled systems)

- Fire containment support (where passive fire resistance is required)

Avoid open-ended terms like “lagging” or “acoustic wrap” in your documentation. Instead, link performance objectives to specific materials and minimum thicknesses suited to each service:

- Chilled water services? Closed-cell foam with vapour barrier

- Hot water/HVAC? Fibreglass or mineral wool with foil facing

- Noisy waste systems? Mineral wool + Mass Loaded Vinyl (MLV) composite

- Riser shafts? Fire-rated lagging with tested acoustic and thermal properties

By locking this detail in early, you reduce ambiguity, avoid sub-par value-engineered substitutions, and give contractors a clear benchmark for both compliance and performance.

Align Materials to System Requirements

Not all insulation materials perform the same way — and the wrong choice can mean underperformance or outright non-compliance.

Key materials to consider include:

- Mineral Wool: Excellent acoustic and fire resistance. Ideal for waste, vent and HVAC systems in high-rise or multi-res settings.

- Closed-Cell Foam: Great for chilled water and refrigeration lines. Provides built-in vapour barrier to prevent condensation.

- Fibreglass: A versatile choice for hot and cold pipework, offering solid thermal resistance at a competitive cost.

- Mass-Loaded Vinyl (MLV): A dense acoustic barrier typically used in conjunction with absorptive materials like mineral wool to control low-frequency vibration and plumbing noise.

Match Insulation Thickness to Section J Requirements

The National Construction Code (NCC) outlines minimum R-values for pipework based on system type, temperature, and application (e.g. internal vs. external). A common oversight in project specs is under-calculating insulation thickness — especially on HVAC or central hot water lines.

Clearly state:

- Required R-values or thermal conductivity (k-values)

- Minimum thickness per pipe diameter

- Application-specific adjustments (e.g. in plant rooms, riser shafts, or roof spaces)

Spec sheets should also note fire performance ratings (e.g. AS/NZS 1530.3) where insulation passes through inter-tenancy walls or fire-rated zones.

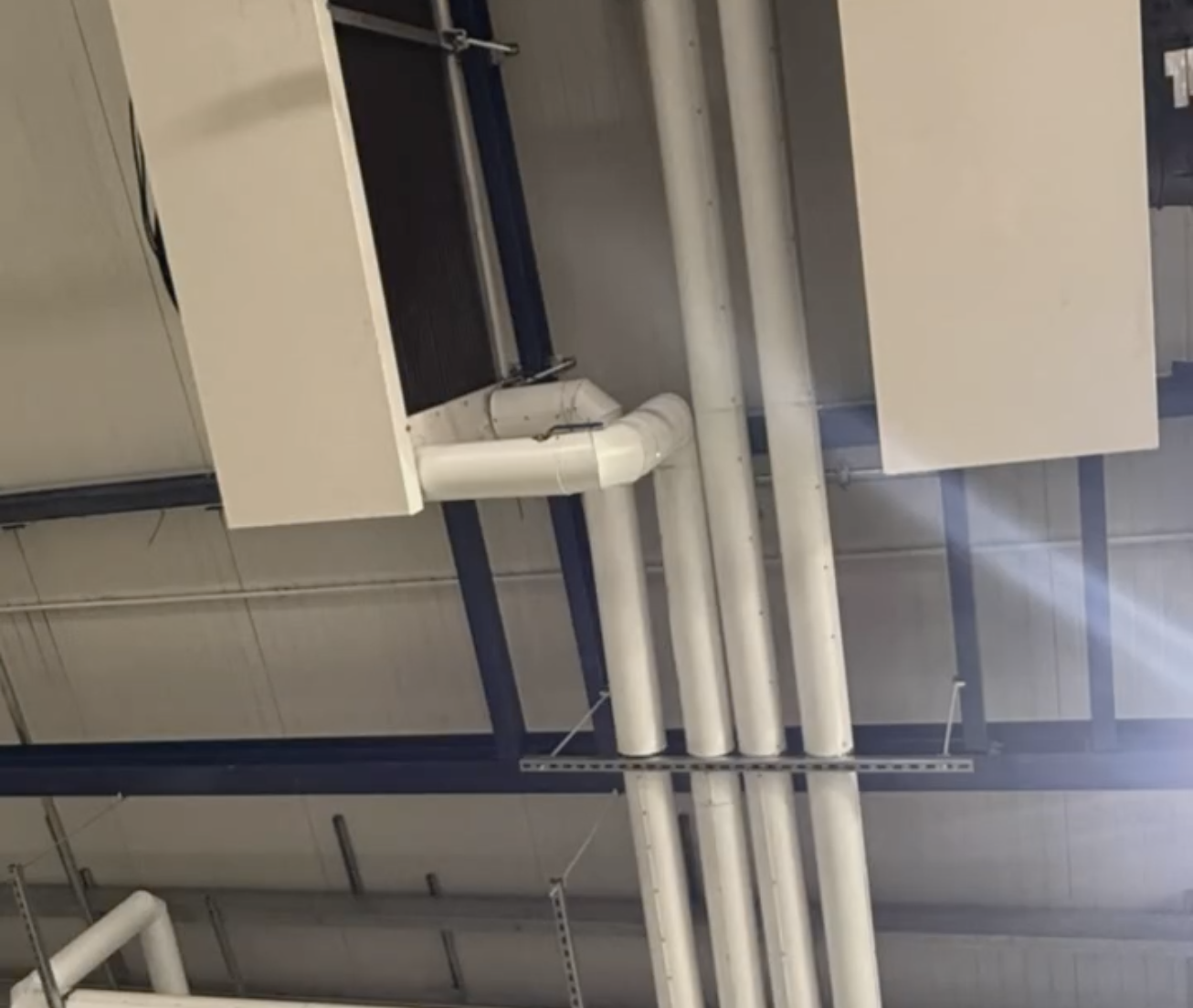

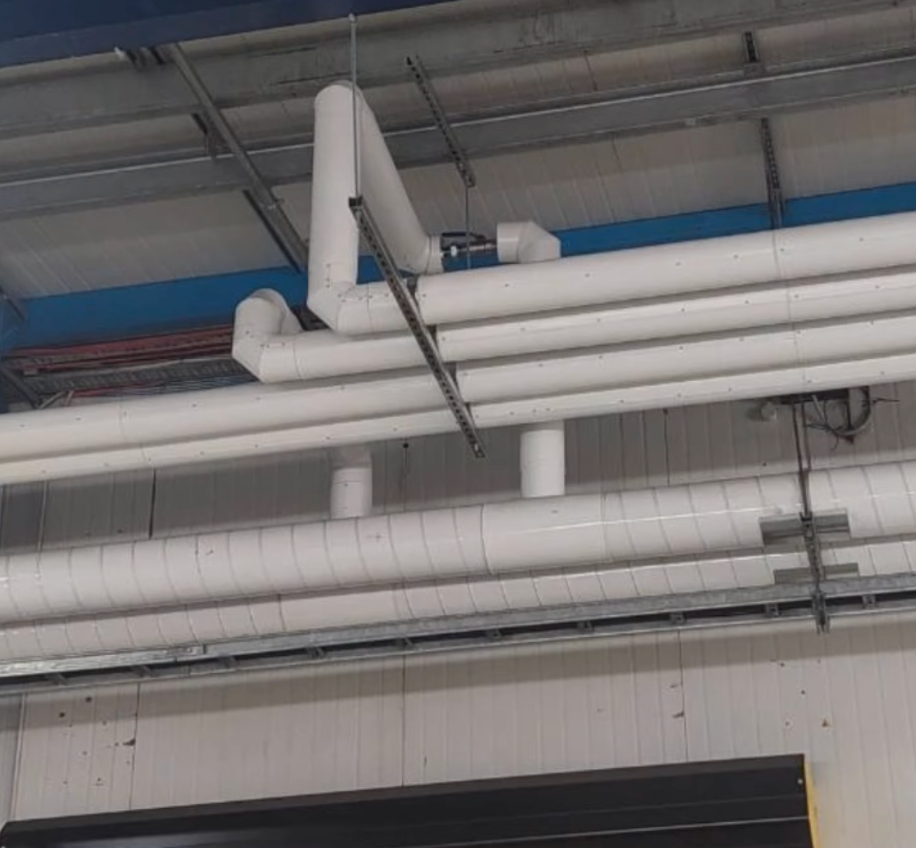

Account for Site Constraints and Installation Practicalities

Ideal specs don’t just meet performance—they also consider real-world install conditions. If your project involves tight risers, high ceilings, or limited access spaces, your spec should note:

- Pre-formed lagging vs. wrap types

- Required support or strapping

- Joint sealing techniques

- Clearances for fire collars or penetrations

- Coordination with other trades (e.g. HVAC or plumbing fit-off timing)

Overlooking install practicality can delay construction and lead to shortcuts or incomplete work.

Include Documentation and Sign-Off Expectations

Lastly, state your expectations for inspection, certification, and handover. This might include:

- Product datasheets

- Installation method statements

- Acoustic or thermal test data

- Compliance certificates (e.g. NCC, AS 1530, ISO)

- Photos or inspection checklists pre-ceiling close-up

This ensures all parties—from builder to certifier—have visibility and accountability throughout the process.

Disclaimer

This article is provided free of charge for public information. We do not guarantee, and accept no legal liability for, the accuracy, reliability, currency, or completeness of the content or any linked material. Users should apply their own judgment and verify the material’s relevance to their needs. This article is a general summary and not a substitute for legal or professional advice. Users should seek appropriate advice for their circumstances. Any third-party views expressed do not necessarily reflect ours or imply endorsement.