Step-by-Step Guide to Installing Acoustic Lagging on PAC Units in Melbourne

Enhance noise control and improve efficiency with this step-by-step guide to installing acoustic lagging on PAC units in Melbourne. Learn the key stages from site assessment to compliant installation, tailored to suit local conditions and regulations.

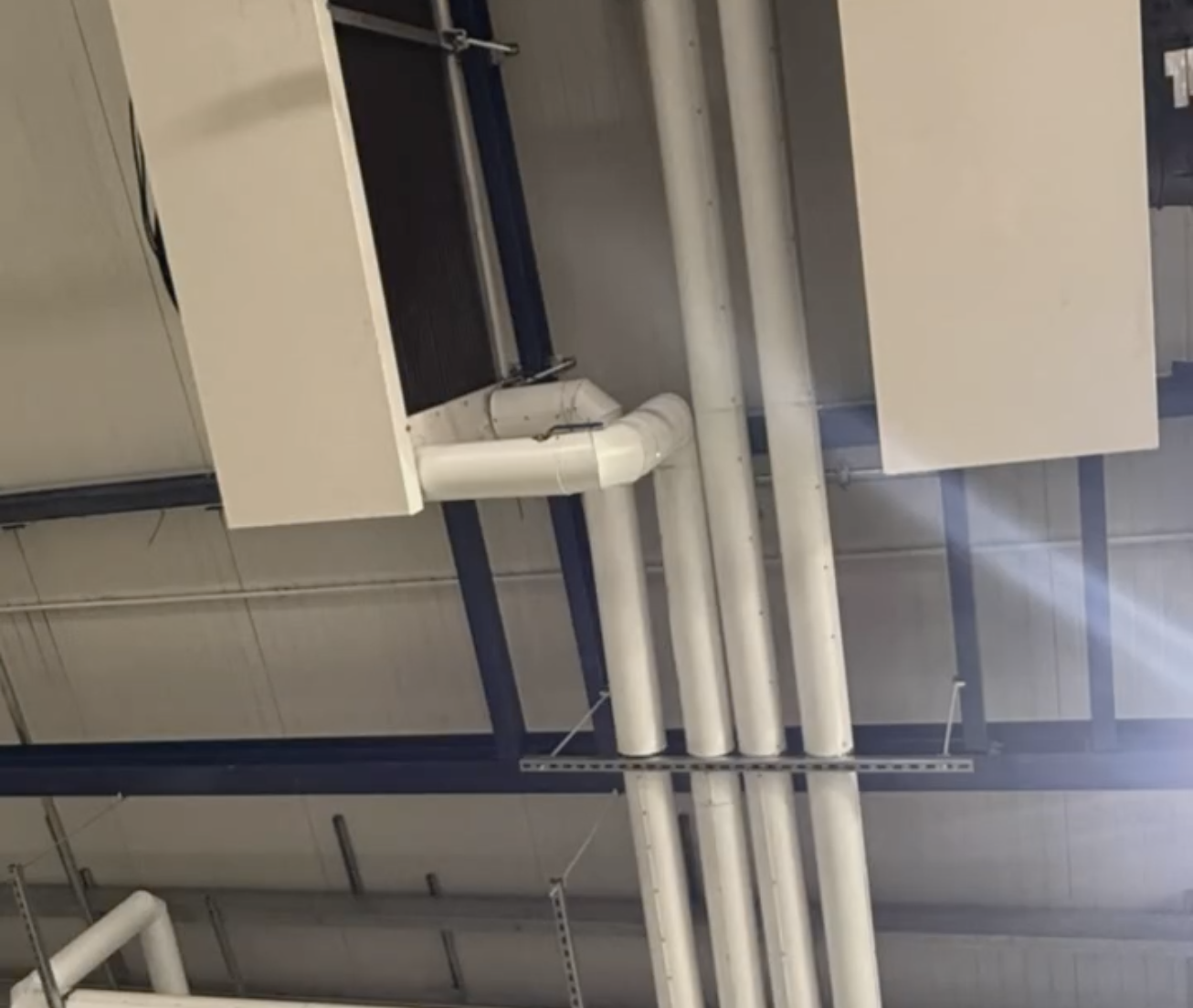

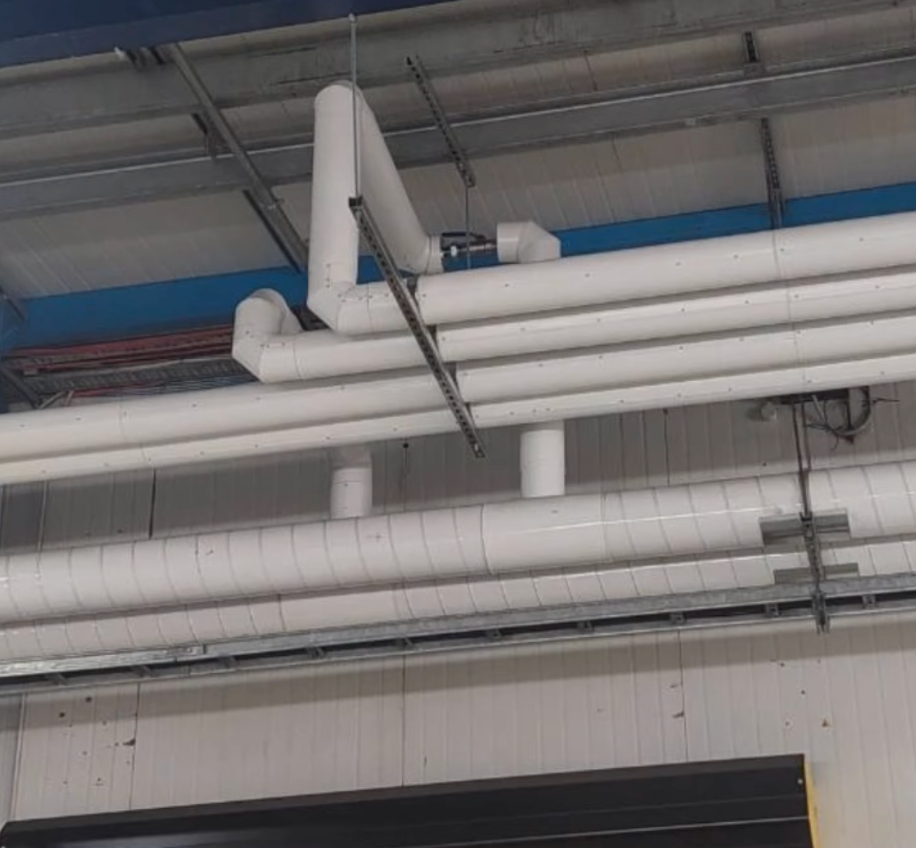

1. Site Inspection & Assessment

Before beginning any acoustic lagging work, a thorough site inspection is essential. This involves assessing the layout and condition of all PAC units, identifying key noise sources such as refrigerant pipes or vibrating components, and checking for any existing insulation. The goal is to understand the scope of the job and tailor the lagging solution to suit the specific needs of the site while ensuring compliance with Melbourne’s building and noise regulations. So, in a nutshell:

- Inspect all PAC units to assess size, pipe layout, noise levels, and existing insulation (if any).

- Identify noise sources (e.g., refrigerant pipes, compressors, ductwork).

2. Choose the Right Acoustic Lagging

Selecting the appropriate acoustic lagging is crucial for effective noise reduction. For PAC units, high-performance materials like foam lagging with a mass-loaded vinyl barrier are ideal, as they dampen both airborne and vibrational noise. It’s important to choose products specifically designed for HVAC applications and ensure they meet Australian standards for fire safety and durability, especially in Melbourne’s variable climate. The right choice ensures long-term acoustic performance and compliance. So, in a nutshell:

- Select high-density acoustic lagging (e.g. foam with mass-loaded vinyl backing) rated for HVAC applications.

- Ensure the material complies with local building codes and fire safety regulations in Melbourne.

3. Surface Preparation

Proper surface preparation ensures the acoustic lagging adheres correctly and performs effectively. Start by cleaning the pipes and ductwork to remove any dust, oil, or old insulation residue. Surfaces should be dry and smooth before applying the lagging. Accurate measurements and neat cutting of materials will help achieve a tight fit, reduce gaps, and make sealing easier during installation. A well-prepared surface sets the foundation for a durable and noise-reducing finish. So, in a nutshell:

- Clean and dry the surfaces of pipes and ducts — remove dust, grease, or old insulation.

- Measure and cut lagging material to size.

4. Installation

In a nutshell:

- Wrap the acoustic lagging tightly around noisy pipes or ducts.

- Seal seams using acoustic-rated tape or adhesive to prevent sound leakage.

- Use cable ties or mechanical fasteners if needed, especially for vertical runs.

5. Finishing & Fire Safety Checks

In a nutshell:

- Ensure all joins are properly sealed and neat.

- Check clearances around hot components to maintain fire safety.

- Apply protective coverings or jackets if required for weatherproofing (for outdoor units).

6. Compliance & Documentation

In a nutshell:

- Make sure the work meets local council noise control regulations and any body corporate requirements.

- Document the installation — include materials used, installation method, and acoustic performance data.

7. Testing (Optional)

Once installation is complete, testing helps verify the effectiveness of the acoustic lagging. This can involve a basic noise level comparison before and after installation or using sound meters for more accurate readings. While not always mandatory, testing provides peace of mind that the solution is working as intended and meets project expectations. It also offers valuable documentation for clients, compliance checks, or future maintenance needs.

- Perform a basic post-installation sound test to confirm noise reduction.

Disclaimer

This website is aimed at disseminating information free of charge for the benefit of the public. We do not guarantee, and accept no legal liability whatsoever arising from or connected to, the accuracy, reliability, currency or completeness of any material contained on this website or on any linked site. We recommend that users exercise their own skill and care with respect to their use of this website and that users carefully evaluate the accuracy, completeness and relevance of the material on the website for their purposes. The material on this website is a summary only of the subject matter covered and is not intended to be nor should it be relied on as a substitute for legal or other professional advice. Users should obtain any appropriate professional advice relevant to their particular circumstances. The material on this website may include the views or recommendations of third parties, which do not necessarily reflect the views of ours, or indicate its commitment to a particular course of action.